XP8 350A

Air Cooled MIG Welding Torch

Rating: 350A, 10.5kW, Mixed Gas (80/20) @ 80% Duty Cycle, EN60974-7 .040″ – 1/16″ / 1.0mm to 1.6mm wires

Rating: 350A, 10.5kW, Mixed Gas (80/20) @ 80% Duty Cycle, EN60974-7 .040″ – 1/16″ / 1.0mm to 1.6mm wires

Amperages and duty cycles alone are arbitrary measures of a torches capability.

For a more accurate appreciation wire type, gas type, flow rate and open circuit voltage must all be taken into consideration.

The XP8 is rated in Amps as a guideline but the Kilowattage requirement of a given application provides a far more accurate method for calculating torch selection.

Kilowattage represents the total power rating required and is calculated as follows:

Welding Amps x Welding Volts |

= kW |

|

|

|

1000 |

(Amps x Volts = Watts , 1000 Watts = 1 kW)

Table to show the affect on XP8 performance when using alternate gas types

| Mixed Gas (80/20) | xx | Mixed Gas (95/5) | xx | 100% CO2 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Amps | kW | Amps | kW | Amps | kW | |||||

| x | XP8-350A | x | 350 | 10.5 | x | 300 | 9.0 | x | 425 | 14.9 | x |

|

|

|||||||||||

Note: All ratings are based on a nominal gas flow of 18lpm. A lower gas flow will result in an increase in working temperature but it will not have any adverse affect as long as the gas flow is within the accepted limits for the welding amperage.

| Model | ||||||

|---|---|---|---|---|---|---|

| Stock Code | 3M | 4M | 5M | Model Description | ||

| XP350A | -30E | -40E | -50E | Welding Torch c/w Euro Fitting | ||

|

|

||||||

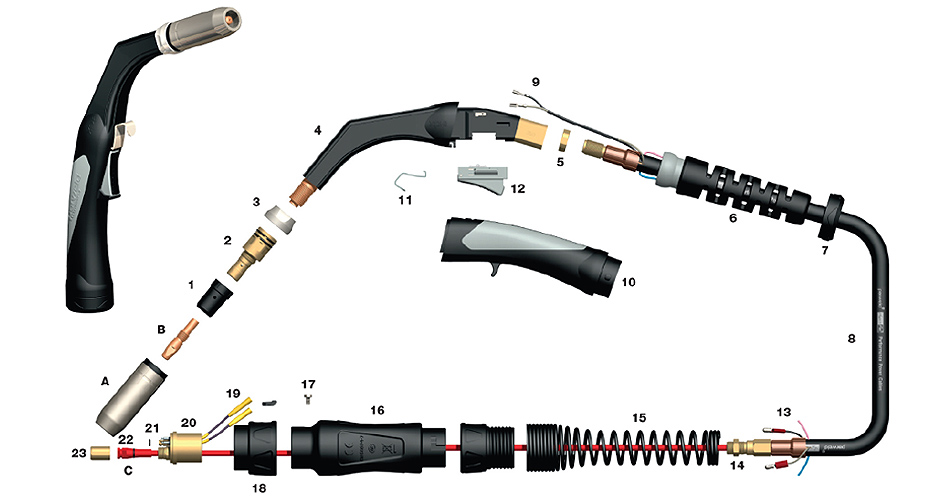

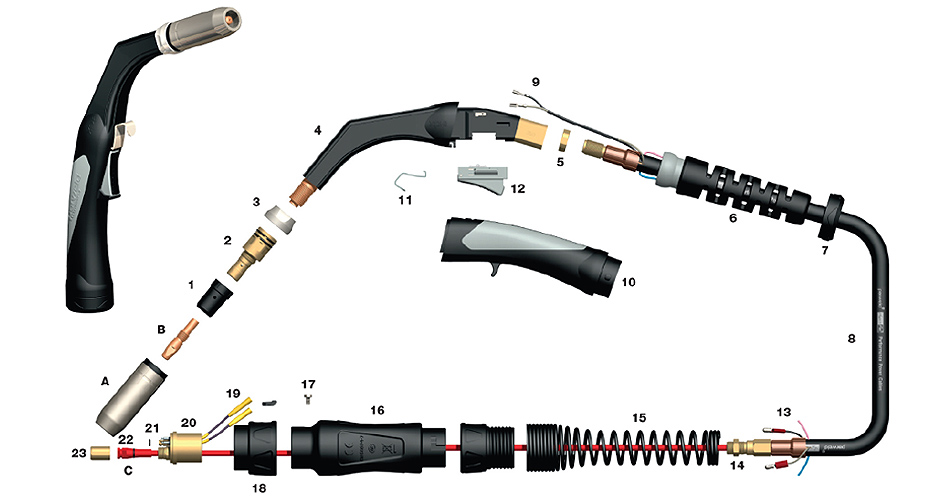

| Nozzles | ||||

|---|---|---|---|---|

| Stock Code | Description | |||

| A | XP3002-13 | Tapered Nozzle 1/2″/13mm | ||

| XP3002-16* | Conical Nozzle 5/8″/16mm | |||

| XP3002-16L | Conical Nozzle 5/8″/16mm-Extended | |||

| XP3002-19 | Cylindrical Nozzle 3/4″/19mm | |||

| XP3002-19L | Cylindrical Nozzle 3/4″/19mm-Extended | |||

|

|

||||

| Contact Tips | ||||

|---|---|---|---|---|

| Stock Code | Description | |||

| B | XP3003-10 | Contact Tip .040″/1.0mm M10 CuCrZr | ||

| XP3003-10A | Contact Tip .0409/1.0mm Aluminium M10 CuCrZr | |||

| XP3003-12* | Contact Tip .045″/1.2mm M10 CuCrZr | |||

| XP3003-12A | Contact Tip .045″/1.2mm Aluminium M10 CuCrZr | |||

| XP3003-13 | Contact Tip .052″/1.3mm9 M10 CuCrZr | |||

| XP3003-14 | Contact Tip .055″/1.4mm M10 CuCrZr | |||

| XP3003-16 | Contact Tip 1/16″/1.6mm M10 CuCrZr | |||

|

|

||||

| Liners | ||||

|---|---|---|---|---|

| Stock Code | Description | |||

| C | XP3524-12-30* | Steel Liner .040″/1.0mm-.045″/1.2mm x 10ft/3m | ||

| XP3524-12-40* | Steel Liner .040″/1.0mm-.045″/1.2mm x 13ft/4m | |||

| XP3524-12-50* | Steel Liner .040″/1.0mm-.045″/1.2mm x 16ft/5m | |||

| XP3524-16-30 | Steel Liner .063″/1.6mm x 10ft/3m | |||

| XP3524-16-40 | Steel Liner .063″/1.6mm x 13ft/4m | |||

| XP3524-16-50 | Steel Liner .063″/1.6mm x 16ft/5m | |||

| NI | XP2024PC-12-30 | Polyamide – Copper Liner .030″-.045″/0.8mm-1.2mm x 10ft/3mt | ||

| XP2024PC-12-40 | Polyamide – Copper Liner .030″-.045″/0.8mm-1.2mm x 13ft/4m | |||

| XP2024PC-12-50 | Polyamide – Copper Liner .030″-.045″/0.8mm-1.2mm x 16ft/5m | |||

| XP3524PC-16-30 | Polyamide – Copper Liner 045″-.063″/1.2mm-1.6mm x 10ft/3m | |||

| XP3524PC-16-40 | Polyamide – Copper Liner 045″-.063″/1.2mm-1.6mm x 13ft/4m | |||

| XP3524PC-16-50 | Polyamide – Copper Liner .045″-.063″/1.2mm-1.6mm x 16ft/5m | |||

| XP2024PS-12-30 | Polyamide – Steel Liner 030″-.045″/0.8mm-1.2mm x 10ft/3m | |||

| XP2024PS-12-40 | Polyamide – Steel Liner .030″-.045″/0.8mm-1.2mm x 13ft/4m | |||

| XP2024PS-12-50 | Polyamide – Steel Liner 030″-.045″/0.8mm-1.2mm x 16ft/5m | |||

| XP3524PS-16-30 | Polyamide – Steel Liner 045″-.063″/1.2mm-1.6mm x 10ft/3m | |||

| XP3524PS-16-40 | Polyamide – Steel Liner .045″-.063″/1.2mm-1.6mm x 13ft/4m | |||

| XP3524PS-16-30 | Polyamide – Steel Liner 045″-.063″/1.2mm-1.6mm x 10ft/3m | |||

| XP3524PS-16-50 | Polyamide – Steel Liner .045″-.063″/1.2 mm-1.6mm x 16ft/5m | |||

|

|

||||

| Components | ||||

|---|---|---|---|---|

| * Denotes Standard Build | ||||

| Stock Code | Description | |||

| 1 | XP3004B* | Diffuser – Moulded c/w Ceramic Insert – M10 Head | ||

| NI | XP3004C | Diffuser – Ceramic – M10 Head | ||

| 2 | XP3505* | Head Assembly-M10 Tips | ||

| 3 | XP3506A* | Aluminium Heat Shield – M10 Head | ||

| NI | XP3506B | Heat Shield – Moulded – M10 Head | ||

| 4 | XP3501 | Swan Neck | ||

| 5 | XP3507 | Lock Nut M14 | ||

| 6 | XP3008 | Ball Joint and Cable Support | ||

| 7 | XP2009 | Handle Lock Nut | ||

| 8 | XP3510-30 | Cable Assembly x 3m/10ft | ||

| XP3510-40 | Cable Assembly x 4m/13ft | |||

| XP3510-50 | Cable Assembly x 5m/16ft | |||

| 9 | XP2011 | Cable Terminal Female | ||

| 10 | XP2012 | Handle Kit c/w Lock Nut | ||

| 11 | XP2013 | Hanger Hook | ||

| 12 | XP2014 | Trigger | ||

| 13 | XP2015 | Cable Terminal Male | ||

| 14 | XP2016 | Lock Nut M12 | ||

| 15 | XP3017 | Cable Support | ||

| 16 | XP2018 | Air Cooled Gun Plug Housing c/w Nut | ||

| 17 | XP2019 | Gun Plug Screw | ||

| 18 | XP2020 | Gun Plug Nut | ||

| 19 | Spring Pin 2 | Spring Pin Assembly | ||

| 20 | XP2022 | Gun Plug Body c/w Spring Pins | ||

| 21 | XP2023 | Gun Plug Body O Ring | ||

| 22 | XP2025 | Liner Nipple O Ring | ||

| 23 | XP2026 | Liner Retaining Nut | ||

As agents for Parweld Ltd, Wescol Ltd, Omega, Stevens Industrial Services, Taurus Electrode, Welding Material Sales and Wilsecure, all our products meet stringent safety regulations ensuring operator safety.