Market leading weld cleaners.

Quality Consumables.

Superior results.

Click links below for details:

Expert in Weld Cleaning

Click links below for details:

The EASYkleen range of weld cleaning machines are second to none when it comes to reliability and performance, but we also place a huge emphasis on the quality of finish our machines produce, which is why we have teamed up with Universities and Material Testing Houses to complete collaborative studies on our machines in comparison to alternative finishing methods such as AC output machines, abrasives and chemical removal.

All EASYkleen machines have a DC only output. This means that these unit are exclusively using the process of electro-polishing when weld cleaning. This results in the highest possible corrosion resistant finish compared with all other post weld finishing methods.

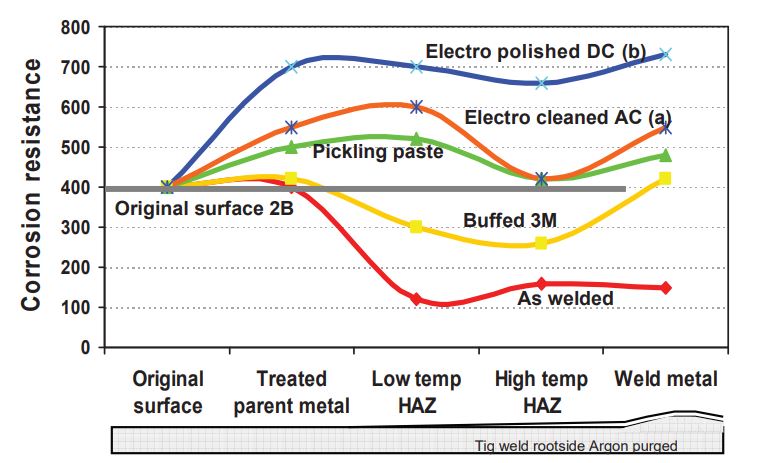

The graph on the right is from a collaborative study with Sandvik Materials and shows the corrosion resistance of different finishing methods, as well as the parent material and as welded.

Figure 4. Effect of cleaning methods on a stainless steel weldment

ALL EASYKLEEN MACHINES

COMPETITOR MACHINES “CLEAN” SETTING

When considering quality of finish, we need to also think about the morphology (shape/structure) of the surface. For stainless steel, the smoother the surface is, the less contamination (dirt, oils, salts, etc.) can adhere, which drastically inhibits bacteria growth and foreign particle entrapment. This gives maximum access to the oxygen required for a strong and continuous passive layer. Dramatically improving the corrosion resistance process.

The Scanning Electron Microscopy (SEM) images show samples of untreated welds and those welds treated, one with AC and one with DC.

AC treated – Surface finish is very irregular which helps contaminants stick or attach to the surface, which increases the pitting potential (corrosion).

DC treated – This smoothing effect, whilst removing a very small amount of material also aids in removal of large grain boundaries which are usual susceptible to pitting (corrosion).

The conclusion is that of all post weld finishing methods tested, the use of a DC output weld cleaning machine, which uses the process of electro-polishing achieves the smoothest finish, will provide the best deterrent against pitting (corrosion).

As agents for Parweld Ltd, Wescol Ltd, Omega, Stevens Industrial Services, Taurus Electrode, Welding Material Sales and Wilsecure, all our products meet stringent safety regulations ensuring operator safety.